BEST TOP 10 CHINA RAPID PROTOTYPING SERVICES MANUFACTURERS FROM SHENZHEN FOR LOW VOLUME PLASTIC INJE

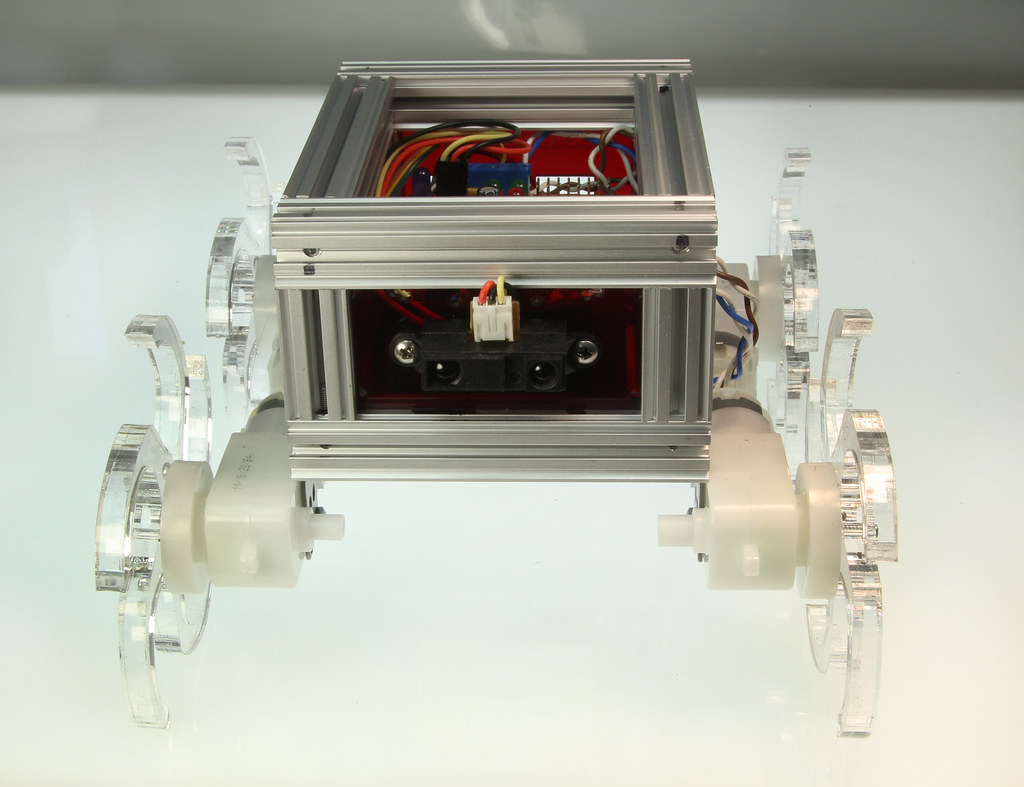

What is Rapid Prototyping? Rapid Prototyping services enables you to quickly, sometimes in a matter of days, create a physical product model. This model can serve as a proof of concept, or even for functionality testing, before you invest in more expensive tooling such as injections molds.

Why do need to provide 3D CAD file for prototyping?

The prototype is a model, a test piece, but it can only be produced in small batches. If you really produce in large quantities, you still have to use a mold, but the mold is more expensive to make. If you make the mold without confirming the usability of the product in all aspects, if anything goes wrong, it’s a big loss.

Bubbles of common problems in injection molding

According to the causes of bubbles, the solutions are as follows:

Warpage and deformation of common problems in injection molding

Warpage and deformation of injection products are very difficult problems. Mainly from the mold design to solve the problem, and the forming conditions of the adjustment effect is very limited. The causes and solutions of warpage and deformation can refer to the following items:

Is Startprototyping’s rapid prototyping service one of the fastest on the market?

The manufacturers worldwide have dedicated themselves to transform all their processes to be at the forefront, as well as the designs of all their customers, since within their main functions is to make all the designs and ideas that need to manufacture their customers, this has generated as a result that all companies dedicated to the manufacture of products have to modify certain techniques to be at the forefront and evolve along with the designs that are requested.

Know More About Quick And Fast Rapid Prototyping Service In Shenzhen China

Fast prototyping is the procedure of rapidly making physical parts to use for testing the look, fit, as well as usefulness of a plan. Conventional assembling procedures can take weeks or months to set up, also a large number of dollars. That is the reason fast prototyping is so significant. It spares time, yet cash too, by and large.

how to avoid deformation in mould manufacturing

In the process of mold manufacturing, deformation often occurs, so how to avoid the deformation in mold manufacturing?

What makes the rapid prototyping services different from the others?

Each manufacturer company knows several processes in order to offer its customers the most complete and competitive services that exist today, and that is that everyone likes to keep their products current and that these represent the best option for all consumers.