What relationship does MRP and ERP have with the production process?

Material Requirement Planning software is a tool that helps the managers calculate the number of materials required for manufacturing. MRP helps in identifying the inventory and then schedules the production process

What is MRP (Materials Requirement Planning) Software?

Material Requirement Planning is a scheduling and inventory control software that calculates the number of components required for manufacturing finished goods and schedule its delivery. It was one of the first integrated systems with the objective of improving production capabilities and purchasing activities.

How an ERP Software Benefits Medical Device Manufacturing Industry?

Quality is paramount in medical device manufacturing industry. A slippage down the line can result in severe consequences which may be life-threatening. This is the reason almost every medical device manufacturer faces a lot of challenges regarding financial management, customer relationship, cost, productivity management and supply chain. Well, it is globally accepted that ERP is a one-stop solution for every hassle in the manufacturing industry.

How ERP Software helps Automotive Manufacturing Companies?

ERP Software integrate all the business functions in an organisation. Automotive manufacturing software streamlines the operations, brings down costs, saves time, improves efficiency, provides 360 degree analysis of the business and better reports. It also help with statutory compliance. Any organization who needs to streamline and integrate disparate systems will require an ERP software.

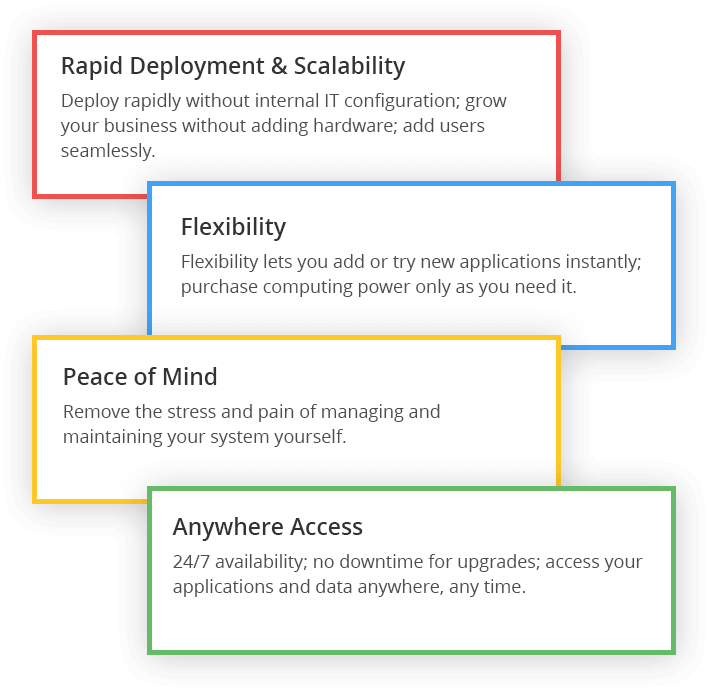

What are the Advantages of Cloud ERP Software?

Simply put, cloud ERP is a suite of ERP apps that are accessible to the users via web browser. Presently, every organization from SMB to MNC is emphasizing more on deploying a trusted cloud-based manufacturing ERP solution that can offer them mobile accessibility for improving productivity and efficiency.