Fluoropolymer Tubing

Ametek FPP is the leading Manufacturer of Fluoropolymer Tubing. It is designed for both ultrahigh purity and highly corrosive applications.

FLEXSIL industry-leading refractory cloth filter Material (AMETEK FPP)

FLEXSIL® recalcitrant fabric channels are intended to extricate dross, slag, unmanageable particles, and non-metallic considerations from liquid metals. FLEXSIL channels were created as a minimal effort, high proficiency option compared to cell earthenware and reticulated artistic froth filtration frameworks. It is produced using exceptionally treated silica filaments FLEXSIL channels are equipped for withstanding pouring temperatures going up to 3000°F (1620°C). FLEXSIL channels are ideal for in-form filtration of dark, moldable, white, compacted graphite, and malleable cast irons, just as non-ferrous aluminum and copper-based metal amalgams. FLEXSIL channels are accessible in a decision of lattice measures and can be sliced or framed...

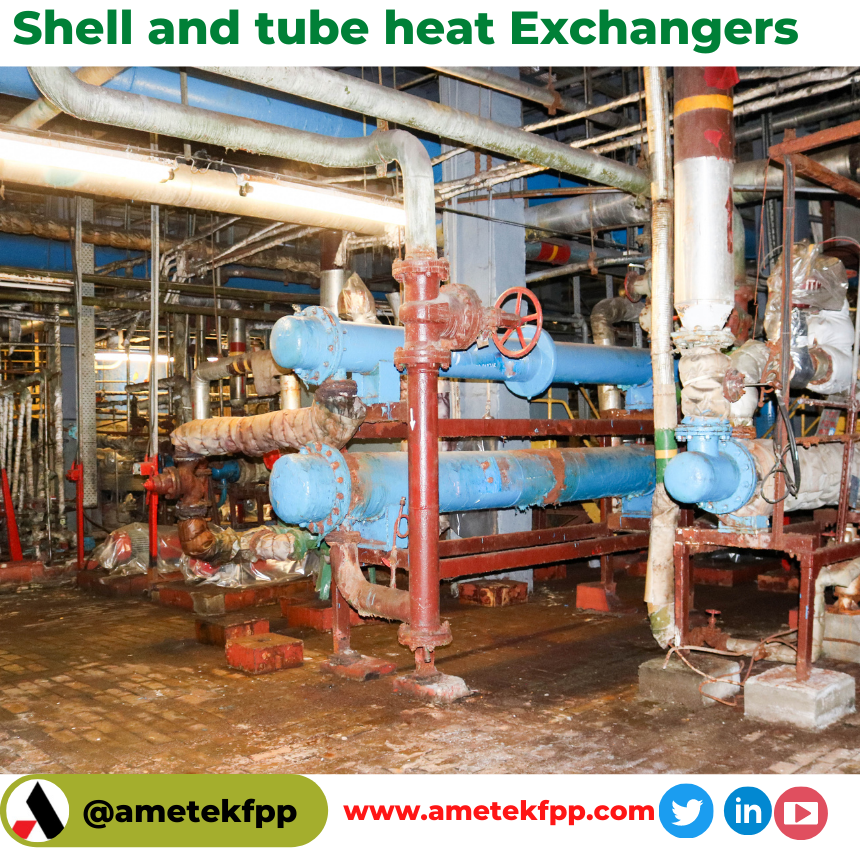

How do shell and tube heat exchangers work?

Heat exchangers are gadgets that move energy in the application of heat, starting with one working liquid then onto the next, regardless of whether that be solids, fluids, or gases. These gadgets are fundamental for refrigeration, power age, and HVAC, which are just the beginning, and come in numerous shapes and sizes that can present warmth or eliminate it.

Shell and tube heat exchanger Types- AMETEKFPP

AMETEK Fluoropolymer product is the leading solution provider for the shell and tube heat exchangers. We are the only company in the market which manufactures the shell and tube with FEP and PFA tubing. Unlike other shell and tube heat exchangers in the market, AMTEK products avoid scaling and fouling by using tubing made from essentially chemically inert fluoropolymers.

An Overview of Fluoropolymer Tubing 2020- AmetekFPP

Ametek FPP is the leading Manufacturer of Fluoropolymer Tubing . It is Designed for both ultrahigh purity and highly corrosive applications.

High Purity Products

AMETEK FPP is one of the Trusted provider of High Purity Products which are prevalent in Semiconductor Fabs, pharmaceutical plants ,high purity liquids.

Why Choose shell and Tube heat Exchangers from Ametek Fpp?

AMETEK is the original manufacturer of fluoropolymer heat exchangers and still the only company that makes FEP and PFA tubing for shell-and-tube heat exchangers.

Immersion coil heat exchangers

Immersion coil heat exchangers have small tubes made of flexible fluoropolymer that are braided into coils. Coils can be installed into almost any tank configuration. Braids are separated by spacers for optimum thermal performance.

Flexsil- Ametek FPP

Flexsil®, the industry-leading refractory cloth filter material, is recognized as the premier filter cloth solution. Ideal for most ferrous alloy filtering and de-gating applications, Flexsil filter material is tailor-formed to meet the needs of both the standard sand foundry and investment casting foundry.